Introduction

In the rapidly evolving landscape of manufacturing, the fourth industrial revolution, or Industry 4.0, represents a seismic shift in how products are produced and delivered. This transformation is powered by digital technologies such as the Internet of Things (IoT), artificial intelligence (AI), robotics, and cloud computing. As a Chief Information Officer (CIO) in the manufacturing sector, I’ve navigated the challenges and opportunities of integrating these technologies, driving not just digital transformation but a complete cultural shift within the organization.

The Heart of Industry 4.0

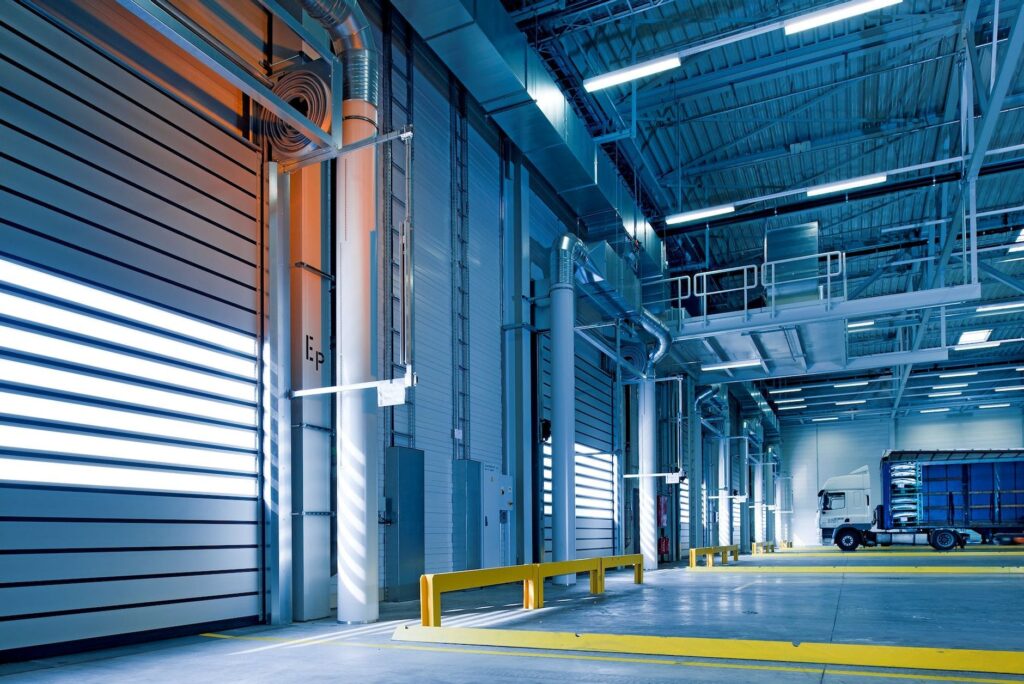

Industry 4.0 isn’t just about technology; it’s about revolutionizing the entire manufacturing ecosystem. It involves creating smart factories where machines are interconnected, processes are automated, and systems are optimized for efficiency and flexibility. This digital transformation enables real-time decision-making, predictive maintenance, and customized production runs, among other benefits.

The CIO’s Strategic Role

Vision and Strategy: Leading Industry 4.0 initiatives requires a clear vision and a strategic roadmap. As a CIO, my role involves not only identifying the right technologies that align with our business goals but also charting a path for their integration that respects our unique operational constraints and opportunities.

Cross-Functional Collaboration: Successful Industry 4.0 implementation demands collaboration across departments. I’ve worked closely with operations, engineering, and supply chain management to ensure that the digital transformation aligns with overall business objectives and enhances rather than disrupts existing processes.

Cultural Transformation: Perhaps the most challenging aspect of Industry 4.0 is managing the cultural shift it necessitates. Embracing a culture of innovation, continuous learning, and adaptability is crucial. My approach has been to lead by example, fostering an environment where experimentation is encouraged, and failures are seen as learning opportunities.

Overcoming Challenges

Adopting Industry 4.0 technologies presents several challenges, from technical integration hurdles to workforce adaptation issues. Addressing these requires a focus on upskilling and reskilling employees, ensuring cybersecurity measures are robust, and maintaining a flexible approach to technology adoption that allows for iterative improvements.

Conclusion

The journey towards Industry 4.0 is complex and ongoing. As CIOs, our leadership is critical in navigating this transformation, requiring us to be visionaries, strategists, and change agents. By embracing these roles, we can lead our manufacturing organizations into a new era of efficiency, innovation, and growth. The road ahead is not without its obstacles, but the potential rewards for our organizations, our employees, and our customers are immense.